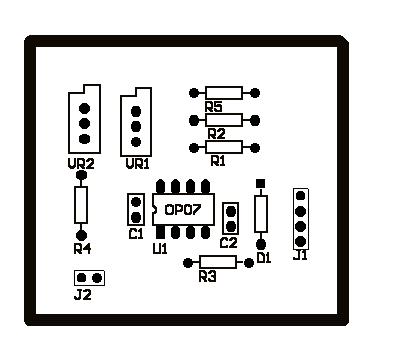

A. PCB layout (Gerber File for Download  ) ) |

|

|

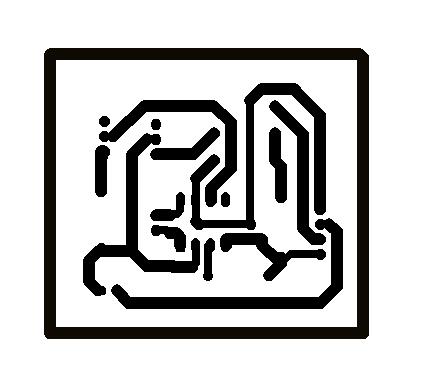

| B.

Develop PCB PCB

Etching Tank system

PCB

Etching can occur in 4 minutes. The tank features graduated markings to

assist in setting appropriate etch ant depth. Normal usage requires a

minimum of 1000cc to a maximum of 1500cc's of etching solution Also

included are some handy wire clips used to hang your PCB in the tank.

This feature makes it easy to lift the board out for easy quick check

of

the board's progress. Or, since the tank is translucent, board progress

can be viewed by shining a light into the tank during the etching

process.

|

| Feature: * Molded plastic tank construction, high impact plastic * Plug in heater to heat ferric chloride or etching chemical * Agitating air pump * Wire board holders that hold board during etching & ease board handling * Graduated markings on molded tank to assist with pouring the etching solution * Typical 4-minute time to remove copper |

Know

more detial for PCB etching |